WILD-IV is the next iteration in the most widely used system of its kind in the world today, with over 300 installed to date.

The hardened electronics used in WILD-IV accurately measures and collects data of loads and impacts translated onto the rail caused by wheels via the rail-mounted strain gauges and front-end processors. The data is an essential component of any performance-based wheel management program.

The data is an essential component of any performance-based wheel management program, the WILD continually monitors rail vehicle health to ensure safe and productive train operations. WILD systems evaluate millions of wheels per day throughout the international rail industry with proven accuracy and reliability.

Product Benefits

Precise impact measurements

Overload and imbalance information

Truck hunting detection

Accurately weigh cars in motion

Live component level health information

Dedicated NA based field service team

Ordering and More Information

For more information or to order a WILD, please contact Will Becker, Technical Sales Engineer, (980) 258-1100 and Jacob Capra, Regional Sales Representative, (412) 815-8762.

Freight

The L.B. Foster WILD is the gold-standard for targeted removal of wheel defects in the freight railroad industry. These defects cause high impacts which can damage vehicles, cargo, and infrastructure. Worse, they can lead to derailments.

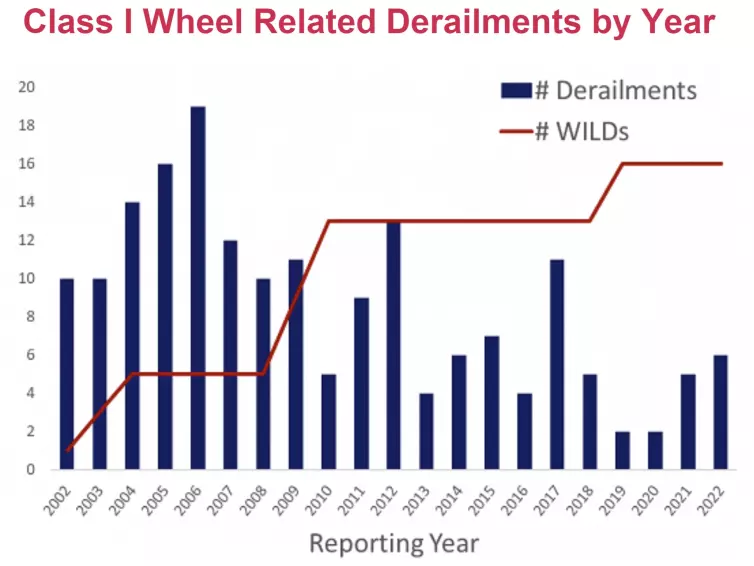

Data provided by the FRA Office of Safety Analysis shows that adoption of WILD products on a class I freight agency’s network correlated with a decrease in wheel and weight related derailments from 13.5 to 5.2 annually.

Class I Wheel Related Derailments by Year

The Wheels, Axles, Bearings, & Lubrication Committee – known as WABL – establishes standards to certify and monitor new rail equipment. When dealing with other agency’s train cars, products must be certified by WABL to be used to inform railroads that cars need maintenance.

WILD products were the basis for and satisfy all WABL requirements related to wheel defect identification and removal, which authorizes railroads to pass the cost of wheel replacement done in the field back to car owners.

Transit

The WILD is a critical component of optimized wheel maintenance. As opposed to wheel maintenance based on time or distance intervals, defects can be identified as soon as they appear, allowing trains to be left in service longer.

Moreover, an optimized wheel maintenance program can lead to longer lifespans for your wheelsets. A report published in 2019 by the FRA showed that by implementing WILDs and utilizing them to inform wheel maintenance, a major U.S. Transit agency extended the lifespan of its wheelsets by over 20% in a single year, with an estimated savings of $1.6M annually. As targeted maintenance continues the lifespan should continue to improve, leading to even greater savings.

You can read the full report here.

Another benefit of targeted wheel defect removal is its effect on noise & vibration. One of the most common complaints of passenger rail riders is a loud, bumpy ride. Often, these discomforts are caused by poor wheel condition.

L.B. Foster is currently partnered with a major Transit agency to quantify the effects of optimized wheel maintenance on noise & vibration, to better inform users of when a wheel is creating an issue for riders, and what sort of improvement in ride quality they can expect by conducting wheel maintenance.